Micro-Hydro Power

Micro-hydro turbines can be a very efficient and convenient form of small-scale renewable electricity. The best locations will be on steep hills, with fast flowing water. If there is not a steep drop, then a larger volume of water flow will be needed instead.

The upfront cost of hydro power can be quite high, but on a suitable site it can be a good long-term investment. On off-grid sites a hydro turbine should be much better in the long term than running a diesel generator for electricity. For larger power outputs, community ownership is a great way of setting up and using hydropower.

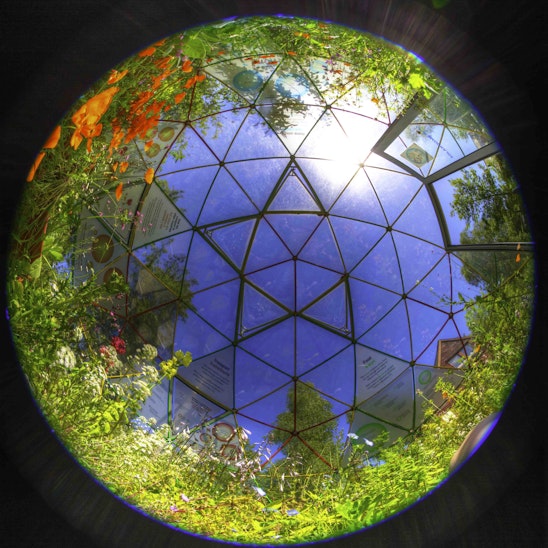

Micro Hydro at CAT

When CAT started in the mid-1970s, it was a big help that we had a great site for harnessing water power. We installed a second-hand micro-hydro turbine to provide much of the electricity we needed around the site. A few years ago CAT upgraded to a new turbine. We’ve also built a new shelter and test rig for running educational workshops on water power.

How much electricity can I generate from a water turbine?

The power you could produce will depends on the ‘head’ of water (the vertical drop) and the flow rate.

To estimate the energy that could be available, multiply the flow rate (in litres per second) by the head (in metres), and then by 10 (acceleration due to gravity). Halve that result, to account for losses and inefficiencies, to get an idea of potential power generation in watts.

As an example, the turbine at CAT uses a flow of up to 20 litres per second, which drops through about 30 metres from our reservoir down to the turbine location. That means the power output is 20 x 30 x 10 x 0.5 = 3000 watts (3 kilowatts).

How much electricity you can generate per year will depend on the seasonal water flows on your site. For example, a 3 kilowatt (kW) turbine running for 4,400 hours (about half of the year) will produce: 3kW x 4400 hours = 13,200 kilowatt-hours (kWh).

What sort of hydro turbine should I use?

To choose a suitable turbine you will need to assess (or hire someone to assess) the available head and flow on your site. As the equation above makes clear, a bigger vertical drop will enable you to harness much more power. Also, because a high head turbine will spin very quickly, there may be no need for complex gearboxes or belts.

You usually need a drop of over 10 metres for a higher head turbine to be viable. These types, such as Pelton or Turgo turbines, are comparatively cheap, easy to install and work well in a fluctuating water flow.

For a low head sites, options include Crossflow and Archimedes Screw turbines. These tend to be much bigger for the same power output because they need to deal with a larger flow rate.

Most schemes are ‘run-of-river’. This doesn’t mean they’re just placed in a river – it means that water is diverted from a stream into a pipe (penstock) or channel when it is available.

How much will a micro hydro turbine cost?

Micro-hydro installations are extremely site-specific. Prices vary widely depending on the type and size of system and how much work you are able to put in yourself. The basic equipment for a 1kW off-grid battery charging system might cost £5,000 to £6,000, plus installation costs.

It might be possible to DIY a small scheme for under £10,000 and in some situations this could be cheaper than paying grid-connection costs. See for example the Powerspout range of turbines, for low or high head sites. Another possible low cost solution is to adapt a water pump so that it operates as a turbine.

For a slightly larger hydro power installation, the total cost might be between £5,000 and £10,000 per kilowatt if professionally installed. There is often an economy of scale, with a 5kW system maybe only costing 50% more than a 2kW system.

Bear in mind that the turbine itself might only be about 20% (one-fifth) of the cost. Putting in place the penstock (pipe) and doing all the other civil engineering work will often cost much more. You need a full installation plan to get a complete breakdown of costs.

A micro-hydro scheme may well cost much more than a solar PV array of similar kilowatt rating. However, if there’s a good water flow most of the year, then the annual output of each kilowatt of hydro power will be several times as much as each kilowatt of solar PV. If a water turbine can be run at about 70% capacity then the output per kilowatt will be about seven times that of a PV array.

Do I need to pay for permission to use the water flow?

There should not be an ongoing cost, but there is an upfront cost for an abstraction licence. This will not guarantee that you can divert water, because the final permission will depend on surveys of the ecological impact of a scheme.

Unfortunately, abstraction licence charges increased greatly in 2022 – one can now cost thousands of pounds. Therefore it’s worth checking the likely costs of this early on. You’d need to compare the cost of the licence to the expected benefits you will get from generating electricity from a micro hydro turbine.

See the related question below for more on licences, including some links.

How much will it pay back?

The savings will depend on how much of the energy you use onsite, and what price you can get for exporting the excess. For what you use onsite, comparison import prices have been dropping, with the July 2024 price cap about 22.36p per unit (kilowatt-hour, kWh). That could continue to drop, but the long term price is hard to predict. In addition, special tariffs are increasingly offering better deals for different patterns of use (such as charging an electric car at night).

For exporting the excess, you can get payments back under the Smart Export Guarantee (SEG) scheme. To claim SEG payments you need a type of smart meter that will measure exported electricity (many first generation smart meters can’t do this). You can shop around and compare the prices offered for your exported electricity. Some companies may offer more than 15 pence per kWh, but some might pay 1p per kWh or less.

Further advice

For more information on working out if micro-hydro power would suit your site, please see the questions below, or some of the courses and workshops CAT offers. For example we offer hydro power workshops for educational groups.

Related Questions

How do I measure flow rate for a micro hydro scheme?There are several methods for measuring flow rate for a potential micro-hydro scheme. The methods vary in complexity and in accuracy.

For a small stream, the easiest way is to divert the entire flow into a container of known size and time how long it takes to fill. Dividing volume by time gives a rough estimate of the flow rate.

For a larger stream, an initial estimate can be made by multiplying the speed of the water by the cross-sectional area. The speed is measured by timing a float along a measured distance of stream (preferably straight and free from obstacles) and multiplying by a factor of between 0.8 (straight smooth channel) and 0.6 (rocky stream). The area can be calculated by measuring the depth at several points across the stream, taking the average and multiplying by the width at that point.

A more accurate method of flow measurement involves building a wooden weir across the stream, with either a V-shaped or rectangular notch cut in it. If the height of water flowing over the weir is measured, then the flow rate can be worked out (see below for more). Although this method involves a lot of work initially, it is then easy to take readings from the weir over a period of time and establish the flow variation.

An entirely different approach is to calculate the catchment area of the stream from a large scale map and then calculate the expected run-off using rainfall statistics such as those available from the Met Office. You’ll need data about geology, rainfall, transpiration and evaporation. Results from this method can be extremely accurate, and they also predict how the flow will vary over the year.

Another option is ‘salt gulp’ – add a salt solution and measure conductivity downstream with a conductivity meter. This is only worth buying if you’re doing a lot of site assessments, as it costs a few hundred pounds.

Notched weirs for assessing water flow

Please Note: you’ll need to use either a computer spreadsheet or scientific calculator to calculate these equations, because of the exponential functions.

- Q is the flow rate in cubic metres per second

- h (in metres) is the height of water above the base of the notch

- L is the width of the rectangular notch, and must be at least 3 x h

The distance from the outer edge of the notch to the stream edge or bank should be at least 2 x h for both types of weir.

For a v-notch (90 degrees) weir: Q = 1.4 x h^2.5 (i.e. h to the power of 2.5, then multiplied by 1.4)

For a rectangular weir: Q = 1.8 x ( L – 0.2 x h ) x h^1.5

The weirs need to be watertight, with accurate angles and sharp edges, and be mounted vertically and at right-angles to the water flow. The weir should be ventilated by air under the crest of falling water. A ‘stilling pond’ just upstream will help to keep the velocity of water before the weir to no more than 0.2 metres per second.

There is much greater detail about these methods and other ways of measuring flows, catchment areas, etc, in the book ‘Going with the Flow’ (by Langley & Curtis). Unfortunately this book is currently out of print, but you may be able to find it through a library or second-hand.

There’s also some information about measuring flow rates on the Appropedia website.

If you are planning to divert more than 20 cubic metres (20,000 litres or about 4,400 gallons) of water per day from a watercourse then you will need an abstraction licence – even though the water is going back into the watercourse after going through a turbine.

Virtually all small hydro projects will require such a license, as even a flow rate of 1 litre per second amounts to 86 cubic metres per day.

The charges in England increased greatly in 2022, and it can now cost a few thousand pounds for an abstraction licence. In other parts of the UK it may be much cheaper.

The abstraction license must be sought from the Environment Agency in England, Natural Resources Wales, or SEPA in Scotland. They will assess effects on river ecology. It’s worth contacting them in good time, as the process could take a few months.

Certain environmental protection measures will generally be linked to the permission given. These include leaving a certain flow in the river (i.e. abstracting only a proportion) and putting in place screening and perhaps a fish pass or ladder.

Larger schemes may involve additional permissions, for example if a reservoir is included.

You’ll also need to contact the local planning office, as planning permission is usually required (unless perhaps an old hydro scheme is being refurbished) for the installation of the structures and pipework involved.

For information about abstraction licences, and the bodies involved in giving permission in different parts of the UK, see the UK government webpage on the environmental management of water. See also the page New hydropower scheme: apply to build one.

For more on the costs, see the charging scheme document for England at Environmental permits and abstraction licences: tables of charges. Table 3.3 on page 119 has a table for hydroelectric power charges. That page also gives links for licensing in Wales, Scotland, and Northern Ireland.

On the Natural Resources Wales page about licences it mentions proposed increases for 2023 that would increase an abstraction licence cost by several thousand pounds.

The British Hydro Association website has a guide to micro hydro, including more detail on planning considerations and permissions.

Old watermill sites can be difficult to adapt for generating electricity, although it’s not impossible. A watermill is an effective way of generating mechanical (rather the electrical) power, to operate machinery directly.

A large, slow-moving body of water gives a high torque (turning force). Waterwheels therefore operate at low rotational speeds (less than 15rpm) and produce very high torque. This makes it difficult to generate electricity.

It’s very challenging to connect a waterwheel with an rpm of about 15rpm to a generator that needs about 15,000 rpm. Motors or generators that run at very low rpm are very large and expensive; even a 1000rpm motor is much bigger than a 1500rpm one.

It’s easier to generate electricity where there’s a fast flow of water that can be channelled to hit a turbine at high pressure. The large size of waterwheels also makes them expensive to construct compared to a water turbine, and they need a lot of maintenance.

It can be possible to adapt a waterwheel. but it may be better to instead look at a dedicated low-head turbine such as a crossflow or Archimedes screw. Or for a small site, the low-head turbine made by Powerspout.

Where there is virtually no drop at all, harnessing water power effectively will be very difficult and may well not be worthwhile.

It is possible to place a ‘zero head’ turbine in a river, or tow one behind a boat, but the output will tend to be very low. Perhaps enough for trickle-charging a 12 volt battery, and maybe cost effective if the alternative is a diesel engine.

The power in a flow

The relevant calculation for the power contained in a flow through a rotor is:

Power (in watts) = ( V^3 ) x 0.5 x p x A

- V is the water flow speed in metres per second – this then needs to be cubed (raised to the power of 3).

- p is the density, which is about 1000 kg per cubic metre for water.

- A is the cross-sectional area swept by the rotor, in square metres.

The efficiency of the turbine will then be a big factor in how much of that power can actually be converted into electricity (or into mechanical power for an undershot waterwheel).

For fixed or towed turbines, the efficiency tends to be quite low. An example of power output is about 100 watts in a flow of 4 metres per second from a rotor diameter of about 30cm. The maximum power in that flow is about (4^3) x 0.5 x 1000 x 0.07 = just over 2000 watts. So the efficiency is just under 5% (100/2000).

A standard micro hydro system (where water is channelled in a pipe) should have at least 50% overall efficiency, after all losses. A small low-head turbine could generate about 1 kilowatt (1000 watts) from a flow of 100 litres per second dropping through 2 metres. So much more energy from a smaller flow, as long as a small head can be created by channeling the water flow over a small distance.

Other issues with a zero head turbine

It will not simply be a matter of placing a propeller-type turbine into a stream. There will be various issues that need to be addressed to ensure a long operating life:

- Debris coming down the stream when it is in spate, and damaging the turbine or mountings.

- Some ground work may have to be done in small streams to make sure there that there is sufficient depth to submerge the turbine at low flows.

- At 12 or 24 volts DC output, heavy cable will be needed to run from the generator to the house, and this can be costly (e.g. if more than 20 metres).

- The turbine should be easily accessed to remove weed build up.

- Flow rates will be very seasonal, so you may well need other power sources to meet electricity needs in the drier months.

A hydraulic ram is a water-powered pump that uses the energy in a large flow of water dropping through a small height to lift a small percentage (about 10%) up to a much higher level.

A ‘compound’ ram pump uses this power to pump a separate body of water. They are very site-specific, but with only two moving parts can be a reliable and cost-effective solution on a suitable site, at around £1,000.

We have a ram pump at CAT. It uses the water flow leaving our hydro turbine, and pumps about 10% of this water up about 3 metres into the air above the lake.

The ram pump is not a new technology. It was first developed around 1800 by one of the Montgolfier brothers – famous as the inventors of hot-air balloons. Ram pumps have been manufactured in the UK ever since, and became very common in rural parts of Britain in the early 20th century.

The increasing availability of mains water and cheap power (for pumping) during the last century led to a decline in their use in the UK, but they remain a reliable, cost-effective, and environmentally friendly option in the right situation. In remote and hilly areas they offer a reliable water pumping option.

For more detailed information, books on Hydraulic Ram Pumps include “Manual On the Hydraulic Ram” (by S B Watt) and “Hydraulic Ram Pumps: a guide to ram pump water supply systems” (by T Jeffrey).

It is possible to adapt certain types of water pump so that they effectively act in reverse, and can be used to generate electricity. This has the potential to be much cheaper – for an output of a few kilowatts it could save several thousand pounds.

The book “Pumps as Turbines: A users guide” (by Arthur Williams) gives practical, technical information on the use of standard pump units as a low-cost alternative to conventional turbines. The focus is on providing stand-alone electricity generation in remote locations.

There’s a recent example of a pump as turbine (PAT) at Tŷ Mawr Wybrnant. The 4kW turbine is expected to feed about 19,000 kWh of electricity into the grid each year. This is a National Trust site and the installation was through Dŵr Uisce – a joint research project of Trinity College Dublin and Bangor University.

Related Pages

Related events

Build a Small Wind Turbine (Only three places left)

5th October 2024

Zero Carbon Britain: Carbon Literacy for Local Authorities Online

8th October 2024

Renewables for Households: Insulation

23rd November 2024Study at CAT: Our Postgraduate Courses

Related news

CAT Conversations – Dr Frances Hill

10th July 2024

CAT Stories – Aber Food Surplus

23rd May 2024

Taking back power

9th April 2024

Why we teach… community solar

9th April 2024

Did you know we are a Charity?

If you have found our Free Information Service useful, why not read more about ways you can support CAT, or make a donation.

Email Sign Up

Keep up to date with all the latest activities, events and online resources by signing up to our emails and following us on social media. And if you'd like to get involved and support our work, we'd love to welcome you as a CAT member.